PIA is a vertically integrated industrial zone, focussed at creating thriving value chains for the textile industry – from raw material sourcing to resource transformation through manufacturing, to exporting final products. The Plateforme Industrielle d’Adétikope is set to become a world-class industrial zone and an ecosystem facilitating the competitive manufacturing of cotton by transforming local raw cotton into textile.

To deliver this ambition, ARISE IIP will work with the Togolese government to attract foreign investors, establish linkages across the whole value chain, organise trade shows for hosted companies to showcase and market their products, and boost exports.

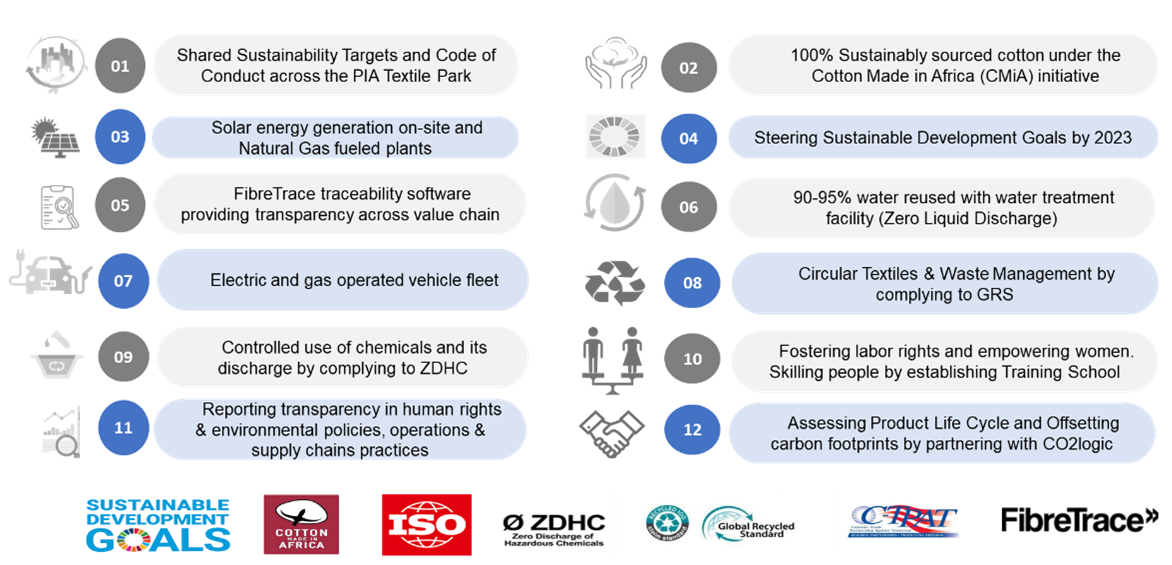

PIA Textile Park : Quick Overview

Environmental Compliance

Traceability and CMiA certified cotton

Skilled Workforce

Preferential market access to US and EU

Recycling and reuse

Competitive production costs

Speed to Market

Social & labour benefits

Fiscal and Non Fiscal Incentives

Business Opportunities

The Perspective Investor can set up a standalone textile process or an Integrated textile unit as per the requirements

Why invest in PIA’s Textile Park?

Infrastructure & Facilities

Other Facilities include Convention Centre/Exhibition Hall, Vocational Training Centre, Testing Laboratory, Rest Room, Canteen & Creche, First Aid Centre/ Medical Centre, Compound Boundary Wall, Main Gate with security, Police Station.

Readymade Factory Sheds

Ready availability of plug & play factory sheds at attractive prices

Rain Water Harvesting and Drainage System

Proper drainage system to channelize storm water along with water storages

Zero Liquid Discharge & Central Effluent Treatment Plant (CETP)

Waste water received through conduit pipeline for treating through CETP and recycled…

Solid Hazardous Waste

Waste generated from the CETP and units are disposed off in the registered and approved disposal sites

Manpower Availability

Togo’s labour force population is expected to grow to 4.2 million by 2030. Togo boasts of its quality of work force in the region. With approximately 70% of its total population under the age of 35 years, Togo is a young and growing country.

Favorable Labour Policies

Guaranteed freedom to hire under flexible labour code

Dedicated vocational training centre to train 7000 textile mill workers and 25,000 garmenting workers

Freedom to bring expat staff during the initial years

Attractive labour costs

Raw Material

Plateforme Industrielle d’Adetikope (PIA) Textile Park is poised to achieve its objective to transform local cotton into high value finished garments.

Abundant presence of cotton within the country

Guaranteed freedom to hire under flexible labour code

Premium cotton is available in the Park at globally competitive prices.

Sustainable CMiA certified cotton is used in the Park

Warehouse for smooth discharge of finished products from the Park and a Raw Material Depot for inward movement and storage of raw material etc.

Market Access

It enjoys preferential duty free market access to US (under AGOA) & EU (under EBA), opening huge market potential

Potential to efficiently serve Nigerian and other land locked countries

Access to regional market of 400 mn+ consumers in ECOWAS nations

With the port of Lomé, Togo is in the direct pathway of international marine lines.

Togo is the centre for regional trade and provides access for West Africa

World-class airport & daily flights to more than 30 international cities including Paris, China, India & USA.

Attractive Fiscal & Non Fiscal Benefits

01

Tax Holidays for Export Oriented Units

02

Zero Corporate Income Tax*

03

Zero Dividends Tax or Income Tax on movable capital*

04

Medium and long term external borrowing facilities available

05

Right to repatriate or transfer capital and profits within the legal framework of foreign exchange regulations.

06

No restrictions on the rights of foreigners to manage local companies. The foreign investor can create a 100% subsidiary.

07

Export oriented industries are allowed to sell upto 25% in local marke

Knit Apparels

Various manufacturing industries in PIA include:

- The Integrated Knitting unit includes Spinning, Knitting, Dyeing, Finishing and Garmenting process for manufacturing an impressive range of Knitted Apparels made with variety of Carded, Combed, Compact Cotton & Spandex yarns.

- This manufacturing unit will be equipped with modern technology through automations across all machineries.

- Knit apparel plant is spread over a total of 9.5 ha area.

- This Factory is equipped with 33,000 spindles for producing combed hosiery yarn of approx. 7,000 tonnes annually in the range of Ne 20s to Ne 40s

- This plant shall produce an approx. 27 million pcs of knit garments annually.

Knit Products

The product basket includes:

- Polo T-Shirts, Round Rib Neck T-Shirts for Men, Women and Children.

- Leggings

- Night Wears

- Under Garments

Knitting Fabrics will be ranging from, Single Jersey in 100% Cotton and Cotton / Spandex, 1 x 1 Rib with Spandex

Our Knitting unit will be specialized in making licensed clothing, licensed nightwear for men, women and children

Construction of the Garment Training Centers in PIA

Thanks to a co-financing with the Togolese State, PIA is implementing two Garment Training Centers (GTC). A recruitment campaign is ongoing to hire and thoroughly train 1,000 Togolese youths before being deployed in textile plants.

- Cutting, garment, and finishing stage.

- Garment manufacturing technology.

- Garment engineering and clothing management techniques.

- Plant layout and workflow design.

- Quality insurance (specifications, control, and audit procedures).

- productivity measures (metrics, production, and efficiency).

- objectives’ determination and production lines management

- lines balancing implementation (insurance of optimized use of the workforce and equipment)

- cost control (excess costs, waste control, use of materials)

- leadership and human resources management

The GTCs will allow Togo to further catalyze its qualified workforce in the Textile sector, which will increase the country’s attractiveness to investors in the global arena.

Yearly Manufacturing Capacity

16.8 MILLION Round neck t-shirts

16.8 MILLION Polo t-shirts

4.2 MILLION Leggings

16.8 MILLION Round neck t-shirts

16.8 MILLION Polo t-shirts

4.2 MILLION Leggings

Ecosystem Approach

PIA’s social impact (CSR) in the textile industry

The company Plateform Industrial Adétikopé SAS, promoter of the project, has created 228 direct and 1405 indirect jobs since the start of PIA’s construction to date. Indirect jobs are composed of those created through the various construction and service provision companies within the zone, almost all of which are Togolese companies owned by Togolese people. This shows that the local workforce is at the forefront of our activities and projects. Furthermore, these numbers do not take in account the direct and indirect jobs created, or that will be created, by the investors. This project has high economic potential and creates jobs due to the sectors targeted, particularly the Textile sector.